Epoxy & polyurethane

These products are available as single or two pack coating systems, with the two pack system being the modern method. The single pack is a one-component paint and the two pack is a reaction type, where base resin and a hardener are mixed together before use. They are available in water based and solvent form; application is dependent upon the environment and substrate.

Each offers benefits in their own right.

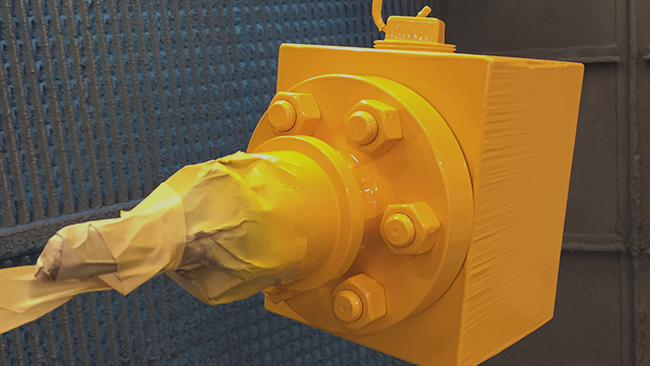

Epoxy coatings are extremely tough, durable and highly resistant to chemicals, abrasion, moisture and alcohol. Epoxy coatings are often chosen for environments where a high performance, chemically resistant coating is required. An example of this would be industrial plant machinery.

Polyurethane coatings are more resistant to UV attack and are typically used in exterior coating specifications.

Polyurethane is the ideal choice for items that cannot be stove enamelled and are are to be placed in an external environment. This is due to the resistance to weathering and UV that polyurethene provides. An example of this application in use would be plastic signs.

Epoxy and polyurethane can also be used together to combine the benefits they both offer. Epoxy and polyurethane coating systems are used increasingly by the marine and offshore industry.

For these types of specifications, we would use an epoxy base or primer and then use polyurethane as a topcoat, thus ensuring an impenetrable coating. In these circumstances we use a minimum 3 coat system, which meets industry standards.